Product Description:

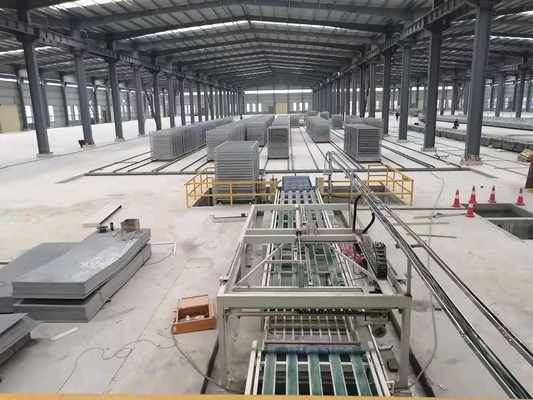

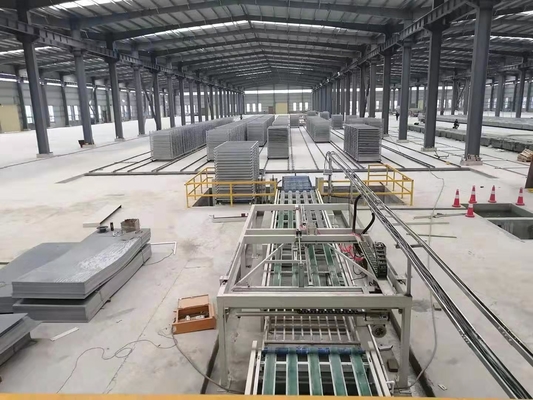

The MgO Board Production Line is a state-of-the-art automatic machine designed to create high-quality MgO boards. This cutting-edge machine produces boards with outstanding bending strength of ≥2.0MPa, fire resistance of A1 Grade, and moisture content of ≤10%. Moreover, it has the capability to control the formaldehyde emission to ≤1.5mg/L. This advanced sulfate MgO board machine is perfect for mass production as it is highly efficient and cost effective.

Features:

- Product Name: MgO Board Production Line

- Compressive Strength: ≥5.0MPa

- Moisture Content: ≤10%

- Sound Insulation: ≥30dB

- Production Capacity: 2-20 Million M2/year

- Bending Strength: ≥2.0MPa

- Automatic MgO Board Machine

- Fully Automatic MgO Board Machine

Technical Parameters:

| Product Name |

MgO Board Production Line |

| Raw Materials |

Magnesium Oxide, Wood Fiber, Perlite, Vermiculite, Etc. |

| Board Thickness |

3-30mm |

| Board Length |

2400-24000mm |

| Compressive Strength |

≥5.0MPa |

| Sound Insulation |

≥30dB |

| Thermal Conductivity |

≤0.2W/m.k |

| Moisture Content |

≤10% |

| Fire Resistance |

A1 Grade |

| Service Life |

≥50 Years |

Applications:

Shandong chuangxin's CX-1 MgO Board Production Line is the ideal choice for producing high-quality MgO boards. This automatic mgo board machine is made in China and features a fire resistance rating of A1 Grade and sound insulation of ≥30dB, and also offers excellent bending strength of ≥2.0MPa. The magnesium oxide board machine is able to produce boards with widths of 600-1220mm, making it ideal for a range of applications.

The MgO Board Production Line is perfect for a range of construction projects, from interior walls and ceilings to exterior walls. It is ideal for new constructions, such as homes, apartment buildings, schools, and shopping centers, and also for renovations and extensions. The boards are easy to install and provide excellent f and sound insulation.

The MgO Board Production Line is a great choice for both industrial and commercial projects. It can be used for factories, warehouses, office buildings, and other industrial and commercial buildings. The boards are highly resistant to fire, moisture, corrosion, and other environmental factors, making them ideal for indoor and outdoor use.

Shandong chuangxin's CX-1 MgO Board Production Line is the perfect solution for producing high-quality, durable MgO boards. The machine is easy to operate and provides excellent performance. It is perfect for a range of construction projects, from interior walls and ceilings to exterior walls, and is ideal for both industrial and commercial applications.

Customization:

Customized Service of MgO Board Production Line

We provide customized service for MgO Board Production Line. Our brand name is Shandong chuangxin and the model number is CX-1. The raw materials of MgO Board Production Line are Magnesium Oxide, Wood Fiber, Perlite, Vermiculite, etc. The bending strength of the board is ≥2.0MPa, and the board width is 600-1220mm, and the board thickness is 3-30mm. And the formaldehyde emission is ≤1.5mg/L.

We specialize in providing high quality magnesium oxide board machine, sulfate mgo board machine and mgo board machine to customers.

Support and Services:

MgO Board Production Line Technical Support and Service

We provide comprehensive technical support and service for our MgO Board Production Line products. We have a team of experienced professionals who are well-versed in the installation, operation, and maintenance of MgO Board Production Lines.

Our technical support team can provide assistance with any technical issues you may have, such as installation, operation, and maintenance of the production line. We can also provide troubleshooting and maintenance tips to help you get the most from your MgO Board Production Line.

We also offer ongoing training and education to ensure that our customers are up-to-date on the latest features and technology of our production line. Our training courses are designed to help you get the most out of your MgO Board Production Line and ensure it is running smoothly.

We are always available to answer your questions and provide you with the best possible service. If you have any questions or concerns, please feel free to contact us and let us know how we can help.

Packing and Shipping:

Packaging and Shipping for MgO Board Production Line

MgO board production line products are packed in wooden crates and shipped on pallets. The wooden crates are properly sealed and labeled with product information and the necessary safety warnings. The pallets are carefully loaded with the wooden crates to ensure secure transportation. The shipping containers are loaded onto the appropriate transportation vehicle and delivered to the customer's location.

FAQ:

Q1: What brand is the MgO Board Production Line?

A1: The MgO Board Production Line is made by Shandong Chuangxin, with the model number CX-1, and made in China.

Q2: What are the advantages of the MgO Board Production Line?

A2: The MgO Board Production Line has many advantages, such as high efficiency, low energy consumption, and reliable performance.

Q3: What type of raw materials are used in the MgO Board Production Line?

A3: The MgO Board Production Line uses magnesium oxide as the main raw material, and other materials such as fiberglass, carbon fiber, and silica powder.

Q4: How much does the MgO Board Production Line cost?

A4: The cost of the MgO Board Production Line depends on the size and complexity of your order. Please contact us for a quotation.

Q5: What is the delivery time for the MgO Board Production Line?

A5: The delivery time for the MgO Board Production Line is usually 15-20 days, depending on the size of your order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!