Product Description:

MgO Board Production Line - A Revolutionary Solution for High Quality Magnesium Oxide Board

The MgO Board Production Line is a state-of-the-art machine designed for the efficient and high-quality production of Magnesium Oxide (MgO) boards. This fully automatic mgo board machine is capable of producing 2-20 million square meters of MgO boards per year, making it the perfect choice for large scale production.

Product Features:

- Formaldehyde Emission: ≤1.5mg/L - Our MgO Board Production Line is designed to meet strict environmental standards, ensuring low formaldehyde emission levels for a healthier and safer working environment.

- Bending Strength: ≥2.0MPa - The mgo board machine is equipped with advanced technology that ensures the final product has a high bending strength, making it suitable for a variety of applications.

- Sound Insulation: ≥30dB - Our production line is designed to produce MgO boards with excellent sound insulation properties, making them ideal for use in soundproofing and noise control applications.

- Production Capacity: 2-20 Million M2/year - With a production capacity of 2-20 million square meters per year, our MgO Board Production Line is perfect for large scale production and can meet the demands of any project.

- Compressive Strength: ≥5.0MPa - Our mgo board machine is capable of producing MgO boards with high compressive strength, making them an ideal choice for use in construction and building materials.

Why Choose Our MgO Board Production Line?

- Advanced Technology - Our production line is equipped with the latest technology, ensuring high-quality and efficient production of MgO boards.

- Cost-effective - Our machine is designed to minimize production costs, making it a cost-effective solution for producing high-quality MgO boards.

- Easy to Operate - The fully automatic mgo board machine is easy to operate, with a user-friendly interface and simple controls.

- Durable and Reliable - Our production line is built to last, with high-quality components and materials that ensure durability and reliability.

- Customizable - We offer customizable options for our production line, allowing you to tailor it to your specific production needs.

Applications:

Our MgO Board Production Line is suitable for a wide range of applications, including:

- Interior and exterior wall cladding

- Soundproofing and noise control

- Fireproofing

- Heat insulation

- Roofing

- Flooring

- And more!

Invest in the Best - Choose Our MgO Board Production Line

With its advanced technology, high production capacity, and exceptional product quality, our MgO Board Production Line is the ultimate solution for your magnesium oxide board production needs. Invest in the best and see the difference in your production process.

Features:

- Product Name: MgO Board Production Line

- Board Density: ≥1.2g/cm3

- Board Length: 2400-24000mm

- Raw Materials: Magnesium Oxide, Wood Fiber, Perlite, Vermiculite, Etc.

- Board Thickness: 3-30mm

- Automatic Control System

- High Efficiency Production

- Low Energy Consumption

- Environmentally Friendly Process

- Flexible Production Capacity

- Easy Maintenance

- Precise Board Thickness Control

- Customizable Board Size

- High Quality End Products

- Multiple Raw Material Options

- Advanced Drying Technology

- Reliable Performance

- Cost-effective Production

Technical Parameters:

| Product Name |

MgO Board Production Line |

| Board Width |

600-1220mm |

| Board Thickness |

3-30mm |

| Board Length |

2400-24000mm |

| Board Density |

≥1.2g/cm3 |

| Moisture Content |

≤10% |

| Thermal Conductivity |

≤0.2W/m.k |

| Raw Materials |

Magnesium Oxide, Wood Fiber, Perlite, Vermiculite, Etc. |

| Service Life |

≥50 Years |

| Formaldehyde Emission |

≤1.5mg/L |

Applications:

MgO Board Production Line Application and Scene

Brand Name: Shandong chuangxin

Model Number: CX-1

Place of Origin: China

Board Length: 2400-24000mm

Moisture Content: ≤10%

Service Life: ≥50 Years

Product Name: MgO Board Production Line

Thermal Conductivity: ≤0.2W/m.k

Introduction

The MgO Board Production Line, also known as the sulfate mgo board machine or fully automatic mgo board machine, is a high-tech equipment that produces magnesium oxide (MgO) boards. It is designed and manufactured by Shandong chuangxin, a leading company in the field of building materials production machinery in China.

Application

The MgO Board Production Line is widely used in the construction industry for its high quality and efficiency in producing MgO boards. These boards are used for various purposes such as wall panels, ceiling boards, fireproof boards, and sound insulation boards. The production line is suitable for both small and large scale production, making it a perfect choice for factories, construction companies, and building material suppliers.

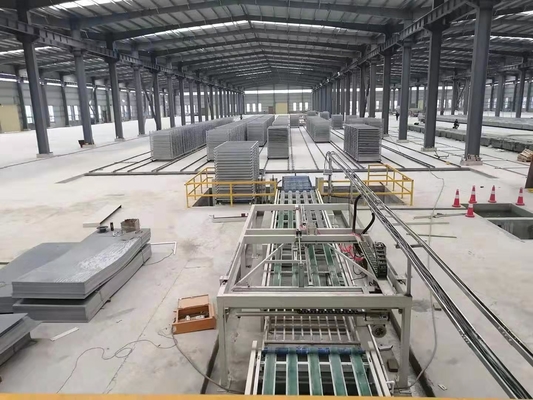

Scene

The MgO Board Production Line is commonly seen in factories and production plants. The production process is fully automated, ensuring smooth and efficient operation. The production line consists of various machines such as mixing machines, forming machines, and cutting machines, each with a specific function in the production process. The whole production process is closely monitored by technicians to ensure the quality of the final product.

The MgO Board Production Line has a long service life of over 50 years, making it a cost-effective and reliable choice for businesses. It also has a high thermal conductivity of ≤0.2W/m.k, making the MgO boards produced by this production line suitable for use in areas with extreme temperature conditions.

Conclusion

In summary, the MgO Board Production Line, with its advanced technology and high-quality output, has become an essential equipment in the construction industry. Its application in producing MgO boards has greatly improved the efficiency and quality of building materials, providing a solid foundation for the development of modern architecture. Choose Shandong chuangxin's MgO Board Production Line, and you will not be disappointed.

Customization:

Customized Service for MgO Board Production Line

Brand Name: Shandong Chuangxin

Model Number: CX-1

Place of Origin: China

Our MgO Board Production Line is designed and manufactured by Shandong Chuangxin, a leading producer in China. Our CX-1 model is highly efficient and reliable for producing high-quality MgO boards.

Moisture Content: ≤10%

Our production line ensures that the moisture content in the boards is carefully controlled and maintained at or below 10%, resulting in a strong and durable finished product.

Board Thickness: 3-30mm

With the flexibility to produce boards ranging from 3mm to 30mm in thickness, our MgO board machine allows for versatility in applications and meets the various needs of our customers.

Formaldehyde Emission: ≤1.5mg/L

We understand the importance of a healthy and eco-friendly environment, which is why our production line ensures that formaldehyde emission is kept at a minimal level of ≤1.5mg/L.

Board Length: 2400-24000mm

Our CX-1 model offers the capability to produce boards with lengths ranging from 2400mm to 24000mm, providing options for different project requirements.

Raw Materials: Magnesium Oxide, Wood Fiber, Perlite, Vermiculite, Etc.

Our production line utilizes high-quality raw materials, including magnesium oxide, wood fiber, perlite, and vermiculite, to ensure the strength, durability, and fire resistance of our MgO boards.

Choose our magnesium oxide board machine for a reliable and efficient solution for your MgO board production needs. Contact us now for more information and to discuss your customized service options.

Packing and Shipping:

MgO Board Production Line Packaging and Shipping

- The MgO Board Production Line will be carefully packaged in wooden cases to ensure safe transportation.

- All necessary parts and components will be securely packed to prevent damage during shipping.

- The packaging will be done according to international export standards.

- Shipping will be arranged by our professional logistics team to ensure timely and efficient delivery.

- We offer various shipping options, including sea, air, and land transportation.

- Customized packaging and shipping solutions are available upon request.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!