Product Description:

The Wall Panel Forming Machine is an advanced Automatic Furniture Making Machine designed to bring efficiency, precision, and durability to your wall panel production process. Equipped with cutting-edge technology and robust construction, this machine is ideal for manufacturers seeking to enhance their production capacity while maintaining high quality. One of the standout features of this Wall Panel Forming Machine is its integration with a Delta Touch Screen, providing an intuitive and user-friendly interface. The Delta Touch Screen allows operators to easily control and monitor the machine’s parameters, ensuring smooth operation and minimizing downtime.

Engineered for fast construction, this Automatic Furniture Making Machine significantly reduces the time required to produce wall panels without compromising on quality. Its design facilitates rapid forming processes, making it perfect for both small-scale workshops and large production facilities. The speed and efficiency offered by this machine enable manufacturers to meet tight deadlines and increase overall productivity. Additionally, the machine’s anti-earthquake feature ensures stable and safe operation even in areas prone to seismic activity. This safety measure protects both the equipment and the operator, providing peace of mind and reducing the risk of damage during unexpected vibrations or shocks.

Customization is a key aspect of this Wall Panel Forming Machine. It supports panel lengths ranging from 2270mm to 3000mm, and these dimensions can be tailored to meet specific project requirements. This flexibility allows manufacturers to produce wall panels suited for various construction needs, ensuring compatibility with different architectural designs and customer preferences. The machine’s voltage rating of 380V ensures it operates efficiently within industrial electrical systems, providing consistent power supply for uninterrupted production.

The material thickness capacity of the machine ranges from 0.3mm to 0.8mm, making it versatile enough to handle different types of metal sheets. This range supports the production of durable and high-quality wall panels that can withstand environmental stressors and provide long-lasting performance. Whether you are working with thin or moderately thick materials, this Automatic Furniture Making Machine delivers precise forming results with minimal material waste.

As an Automatic Furniture Making Machine, this Wall Panel Forming Machine is designed to simplify and automate the wall panel production process. By reducing manual intervention, it minimizes errors and enhances consistency across all panels produced. The automation capabilities enable continuous operation, which is crucial for large-scale manufacturing environments where efficiency and output volume are critical. Furthermore, the machine’s robust design ensures low maintenance requirements and long service life, making it a cost-effective investment for furniture and construction manufacturers.

In summary, the Wall Panel Forming Machine stands out as a reliable, efficient, and customizable solution for wall panel manufacturing. Its Delta Touch Screen interface, fast construction capabilities, and anti-earthquake features make it a superior choice for modern production facilities. With customizable panel lengths from 2270mm to 3000mm, a voltage rating of 380V, and material thickness compatibility between 0.3mm and 0.8mm, this machine caters to a wide range of industrial needs. As an Automatic Furniture Making Machine, it delivers precision, speed, and safety, helping manufacturers achieve optimal production results while maintaining high standards of quality. Whether you are expanding your production line or upgrading existing equipment, this Wall Panel Forming Machine is an excellent addition to your manufacturing arsenal.

Applications:

The Wall Panel Forming Machine, model CX-1, from the reputable brand Shandong Chuangxin, is an advanced Automatic Furniture Making Machine designed to meet the evolving needs of modern construction and furniture manufacturing industries. Originating from China and certified with CE standards, this machine ensures high-quality performance and compliance with international safety regulations. Its robust design, featuring Cr12 roller material, guarantees durability and precision in producing wall panels, making it an indispensable tool for automatic furniture making processes.

One of the standout features of the CX-1 Wall Panel Forming Machine is its fast construction capability. This allows manufacturers and builders to significantly reduce production time, enhancing overall efficiency. The machine operates on a 380V, 50HZ, 3-phase power supply, ensuring stable and reliable performance throughout extended work periods. Additionally, its anti-earthquake design provides extra safety and stability, especially important in regions prone to seismic activity, making it highly suitable for construction projects requiring stringent safety standards.

The machine comes in customizable colors as per customer requirements, allowing businesses to align the equipment’s appearance with their branding or factory aesthetics. Shandong Chuangxin offers a 12-month guaranty on the CX-1 model, providing peace of mind and assurance of quality. The packaging is handled with care, using a sturdy wood package to ensure safe delivery. With a delivery time of approximately 40 days and flexible payment terms including LC and T/T, clients can conveniently plan their procurement schedules.

The Wall Panel Forming Machine is ideal for various application occasions and scenarios, such as large-scale furniture manufacturing plants, prefabricated housing projects, and interior decoration enterprises. It excels in producing wall panels used in automatic furniture making, streamlining the production line and reducing manual labor. Whether in factory settings or on-site construction environments, this machine’s automatic features and reliable performance help increase productivity and product consistency.

Moreover, the minimum order quantity of just one unit makes it accessible for small to medium enterprises looking to upgrade their production capabilities without large upfront investments. Priced competitively at $30,000, the CX-1 Wall Panel Forming Machine offers excellent value for its advanced technology and durability. In summary, this Automatic Furniture Making Machine from Shandong Chuangxin is a versatile, efficient, and safe solution tailored for modern furniture and construction industries aiming for fast, high-quality wall panel production.

Customization:

Shandong chuangxin proudly presents the Wall Panel Forming Machine, model CX-1, a top-tier product originating from China and certified with CE standards. This advanced machine, priced at $30,000, offers exceptional performance with a production capacity of 1500 sheets, making it ideal for large-scale manufacturing needs.

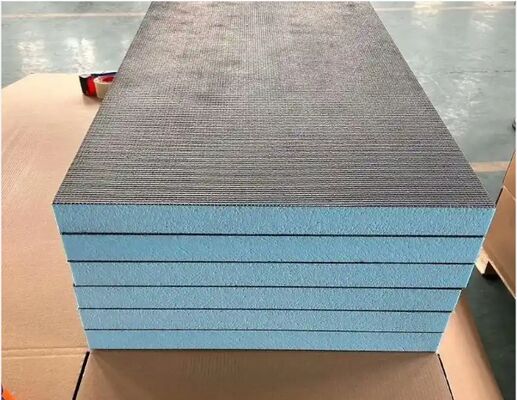

The CX-1 features an automatic EPS foaming machine, ensuring efficient and consistent panel forming. Its remarkable fireproof capability allows panels to withstand 4 hours under 1000 degrees, providing superior safety and durability for construction applications.

Designed to operate at 380V, 50HZ, 3 Phase, this Wall Panel Machine is compatible with standard industrial power supplies. Packaging is securely done with wood packages, ensuring safe delivery within 40 days after order confirmation. Payment terms include LC and T/T, with a minimum order quantity of just 1 unit.

As a versatile solution, the CX-1 caters to industries requiring Double Wall Paper Cup Machine technology and Automatic Furniture Making Machine processes, seamlessly integrating into various production lines. Whether you are looking for an Automatic Furniture Making Machine or specialized wall panel equipment, the Shandong chuangxin CX-1 delivers quality and reliability.

Support and Services:

Our Wall Panel Forming Machine is designed to deliver high precision and efficiency in producing various types of wall panels. To ensure optimal performance and longevity of the machine, we offer comprehensive technical support and services.

Technical Support:

We provide expert guidance on installation, operation, and maintenance of the Wall Panel Forming Machine. Our technical team is available to assist with troubleshooting, machine calibration, and software updates. We also offer detailed user manuals and instructional materials to help you maximize the machine’s capabilities.

Maintenance Services:

Regular maintenance is essential for the smooth functioning of the Wall Panel Forming Machine. We offer scheduled maintenance services, including inspection, lubrication, parts replacement, and cleaning. Our service technicians ensure that your machine operates at peak efficiency and reduce the risk of unplanned downtime.

Spare Parts and Upgrades:

We supply genuine spare parts and accessories to keep your machine running reliably. Additionally, we provide upgrade options for hardware and software to enhance performance and incorporate the latest technological advancements.

Training:

To empower your team, we offer comprehensive training programs covering machine operation, safety protocols, and maintenance procedures. Our training can be conducted on-site or remotely, tailored to your specific needs.

Warranty and After-Sales Service:

The Wall Panel Forming Machine comes with a standard warranty covering manufacturing defects. Our after-sales service ensures prompt response and resolution to any issues that may arise, minimizing disruption to your operations.

By choosing our Wall Panel Forming Machine, you gain access to dedicated technical support and a range of services designed to keep your production line running efficiently and reliably.

Packing and Shipping:

Our Wall Panel Forming Machine is carefully packaged to ensure it reaches you in perfect condition. Each machine is securely wrapped with protective materials and reinforced with wooden crates to prevent any damage during transit. All delicate components are cushioned with foam padding, and the entire package is sealed to protect against moisture and dust.

For shipping, we offer flexible options including sea freight, air freight, and land transportation, depending on your location and urgency. The machine is loaded using appropriate lifting equipment to avoid any impact or scratches. We provide detailed shipping documentation and tracking information to keep you informed throughout the delivery process.

Upon arrival, our team is available to assist with installation guidance and after-sales support to ensure your Wall Panel Forming Machine operates smoothly from day one.

FAQ:

Q1: What is the brand and model of the Wall Panel Forming Machine?

A1: The Wall Panel Forming Machine is from the brand Shandong Chuangxin, and the model number is CX-1.

Q2: Where is the Wall Panel Forming Machine manufactured?

A2: This machine is manufactured in China.

Q3: What certifications does the Wall Panel Forming Machine have?

A3: The machine is CE certified, ensuring it meets European safety and quality standards.

Q4: What is the minimum order quantity and price for the Wall Panel Forming Machine?

A4: The minimum order quantity is 1 unit, and the price is $30,000 per unit.

Q5: What are the packaging and delivery details for this machine?

A5: The Wall Panel Forming Machine is packed in a wooden package to ensure safe transport, and the delivery time is approximately 40 days after order confirmation.

Q6: What payment terms are accepted for purchasing the Wall Panel Forming Machine?

A6: We accept payment via Letter of Credit (LC) and Telegraphic Transfer (T/T).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!