Product Description:

The Sandwich Panel Machine is an advanced and highly efficient piece of equipment designed to manufacture high-quality sandwich panels with precision and consistency. Specifically engineered to cater to the growing demands of the construction industry, this machine is perfect for producing panels that are widely used in building walls, roofs, and cold storage facilities. One of the standout features of this machine is its ability to handle panel widths ranging from 1000 to 1200 mm, making it versatile enough to accommodate various construction needs and specifications.

This machine utilizes EPS (Expanded Polystyrene) as the core material, which is well-known for its excellent insulation properties, lightweight nature, and cost-effectiveness. EPS core material ensures that the sandwich panels produced have superior thermal insulation, making them ideal for energy-efficient buildings. This also contributes to the overall strength and durability of the panels, providing robust protection against weather elements. The incorporation of EPS as the core material highlights the machine’s focus on producing environmentally friendly and sustainable construction materials.

The Sandwich Panel Machine operates efficiently within an operating temperature range of -10°C to 45°C, allowing it to function reliably in diverse climatic conditions. This wide operating temperature range ensures that the machine maintains consistent performance whether it is used in colder or warmer environments. This adaptability makes the machine a valuable asset for manufacturers located in different geographical regions, guaranteeing uninterrupted production regardless of external temperature variations.

Equipped with electric power as its motive force, the Sandwich Panel Machine delivers smooth and stable operation. Electric power not only makes the machine more energy-efficient but also reduces noise pollution and emissions compared to traditional fuel-powered machines. This aligns with modern industrial standards that emphasize sustainability and environmentally friendly manufacturing practices. The electric-powered system also allows for precise control over the machine’s functions, enhancing the quality and uniformity of the sandwich panels produced.

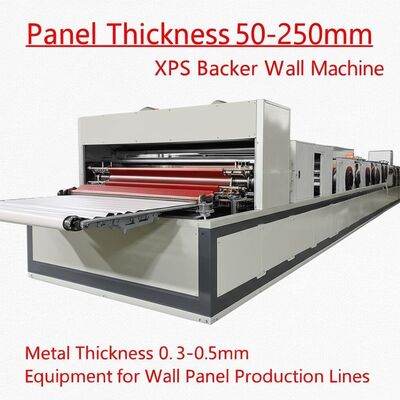

The machine supports a range of panel thicknesses from 50 mm to 250 mm, providing manufacturers with the flexibility to create panels that meet specific insulation and structural requirements. Whether it is for lightweight partition walls or heavy-duty external cladding, the Sandwich Panel Machine can accommodate various thicknesses, making it a versatile solution for different construction projects. This range of thickness options ensures that the panels can be customized based on the thermal insulation needs, load-bearing requirements, and aesthetic preferences of the end-users.

In addition to its technical specifications, the Sandwich Panel Machine is designed for ease of use and maintenance. Its user-friendly interface and automated processes minimize the need for extensive manual intervention, thereby reducing labor costs and increasing production efficiency. The machine’s robust construction ensures long-term durability and minimal downtime, making it a reliable choice for manufacturers aiming for high productivity and consistent quality.

The Sandwich Panel Machine is particularly recognized as a Backer wall panel machine, known for its outstanding performance in producing backer wall panels that serve as essential components in modern building construction. The Backer wall panel machine capability ensures that the panels produced have excellent bonding strength between the EPS core and the outer metal sheets, resulting in panels that are both strong and thermally efficient. This makes the Backer wall panel machine an indispensable tool for manufacturers focused on producing superior backer wall panels for commercial and residential projects.

Furthermore, the Backer wall panel machine functionality integrated within this Sandwich Panel Machine allows for efficient and rapid production cycles, helping manufacturers meet tight deadlines without compromising on quality. The machine’s precise control systems and high-quality components ensure that every panel produced maintains consistent thickness, flatness, and insulation performance. This consistency is critical in the construction industry where quality assurance and adherence to standards are paramount.

In conclusion, the Sandwich Panel Machine is a state-of-the-art Backer wall panel machine that delivers exceptional performance, versatility, and reliability. With its capability to produce panels with widths between 1000 to 1200 mm, core material EPS, operating temperature range from -10°C to 45°C, electric power motive force, and panel thickness options from 50 mm to 250 mm, it is an ideal solution for manufacturers looking to produce high-quality sandwich panels. Whether you are aiming to manufacture insulated wall panels, roof panels, or backer wall panels, this machine offers the efficiency, precision, and durability required to meet the demands of modern construction projects. Investing in this Backer wall panel machine means ensuring superior product quality, enhanced production efficiency, and sustainable manufacturing processes that will drive your business forward in the competitive construction materials market.

Features:

-

Product Name: Sandwich Panel Machine

-

Operating Temperature Range: -10°C To 45°C

-

PLC Brand: Delta

-

Metal Thickness: 0.3-0.5mm

-

Panel Width: 1000-1200 mm

-

Treatment: Heat Treatment

-

Specialized XPS Backer Wall Panel Machine for high-quality panel production

-

Reliable Backer Wall Panel Machine designed for efficiency and durability

-

Advanced Backer Wall Panel Machine technology ensuring precise manufacturing

Technical Parameters:

|

Plc Brand

|

Delta

|

|

Panel Width

|

1000-1200 Mm

|

|

Treatment

|

Heat Treatment

|

|

Razor Blades Material

|

Cr12

|

|

Metal Thickness

|

0.3-0.5mm

|

|

Operating Temperature Range

|

-10°C To 45°C

|

|

Core Material

|

EPS

|

|

Total Power

|

15-30 KW

|

|

Motive Force

|

Electric Power

|

|

Line Length

|

55m

|

Applications:

The Chuangxin XD Sandwich Panel Machine, proudly made in CHINA and CE certified, is a versatile and efficient solution designed to meet various industrial needs. With a total power range of 15-30 KW and an electric motive force, this machine ensures reliable performance and energy efficiency. It is specially engineered to work with EPS as the core material, producing high-quality sandwich panels that are widely used in construction and insulation applications. Featuring razor blades made from durable Cr12 material, the machine guarantees precision cutting and long-lasting operation, making it an excellent investment for manufacturers.

One of the primary application occasions for the Chuangxin XD Sandwich Panel Machine is in the production of backer wall panels. These panels are essential in modern building construction, providing structural support and insulation for both residential and commercial buildings. The machine’s capacity to produce panels up to 32 meters in size allows for large-scale projects, including industrial warehouses, cold storage facilities, and commercial complexes, where efficient insulation and sturdy wall structures are critical.

The XPS Backer Wall Panel Machine variant of this product is particularly useful in scenarios demanding enhanced thermal insulation and moisture resistance. This makes it ideal for use in environments such as refrigerated storage units, clean rooms, and energy-efficient buildings. Additionally, the Chuangxin XD model’s adaptability to different core materials, combined with its robust electric power system, allows manufacturers to customize panel specifications according to specific project requirements.

Manufacturers and contractors looking for a reliable backer wall panel machine will find the Chuangxin XD model an outstanding choice due to its blend of advanced technology, ease of use, and durability. With a minimum order quantity of just one unit and a competitive price of 60000, this machine is accessible to both small-scale and large-scale producers. Whether it’s for producing standard backer wall panels or specialized XPS backer wall panels, the Chuangxin XD Sandwich Panel Machine stands out as a powerful, precise, and cost-effective solution in the construction machinery market.

Customization:

Chuangxin offers the XD model XPS Backer Wall Panel Machine, a state-of-the-art Backer wall panel machine designed to meet diverse production needs. Originating from CHINA and certified with CE, this machine guarantees quality and reliability. With a minimum order quantity of just 1 unit and a competitive price of 60000, it is an excellent investment for your manufacturing line.

The XD model operates efficiently within an operating temperature range of -10°C to 45°C and features a line length of 55 meters, ensuring high productivity. Powered by electric power with a total power consumption of 15-30 KW, it delivers consistent performance while maintaining energy efficiency. The machine utilizes EPS as the core material, optimizing the production of durable and lightweight panels.

Our XPS Backer Wall Panel Machine is engineered to enhance your production capabilities, providing precision and durability in every panel produced. Choose Chuangxin’s Backer wall panel machine for cutting-edge technology and dependable operation tailored to your business needs.

Support and Services:

Our Sandwich Panel Machine is designed to provide efficient and reliable production of high-quality sandwich panels. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services tailored to your needs.

Our technical support team is available to assist you with installation guidance, operational training, and troubleshooting. We provide detailed manuals and video tutorials to help you understand the machine’s features and maintenance requirements.

Regular maintenance services are available to keep your Sandwich Panel Machine running smoothly. These services include routine inspections, parts replacement, and software updates when applicable. Our skilled technicians use genuine spare parts to maintain the integrity and performance of your equipment.

In case of any technical issues, our support team can remotely diagnose problems and provide step-by-step solutions. For complex repairs, we offer on-site service visits to minimize downtime and ensure your production line remains efficient.

We also provide customization options to adapt the machine to specific production needs, including adjustments in panel thickness, width, and core materials. Our engineering team works closely with customers to deliver tailored solutions that meet unique project requirements.

To maximize your investment, we recommend scheduled training sessions for your operators and maintenance staff. This ensures proper usage and helps prevent common operational errors, extending the machine’s service life.

Trust our Product Technical Support and Services to keep your Sandwich Panel Machine operating at peak performance, enabling you to produce durable and energy-efficient sandwich panels consistently.

FAQ:

Q1: What is the brand and model of the Sandwich Panel Machine?

A1: The Sandwich Panel Machine is branded Chuangxin, and the model number is XD.

Q2: Where is the Sandwich Panel Machine manufactured?

A2: The Sandwich Panel Machine is made in China.

Q3: Does the Sandwich Panel Machine have any certifications?

A3: Yes, the Sandwich Panel Machine has CE certification, ensuring it meets European safety and quality standards.

Q4: What is the minimum order quantity for purchasing this machine?

A4: The minimum order quantity for the Chuangxin Sandwich Panel Machine model XD is 1 unit.

Q5: What is the price of the Sandwich Panel Machine?

A5: The price for one unit of the Sandwich Panel Machine model XD is 60,000 USD.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!