Decorative Mgo Sandwich Wall Panel Production Line with Mgo/Mgcl2/Fiber glass mesh

1. product

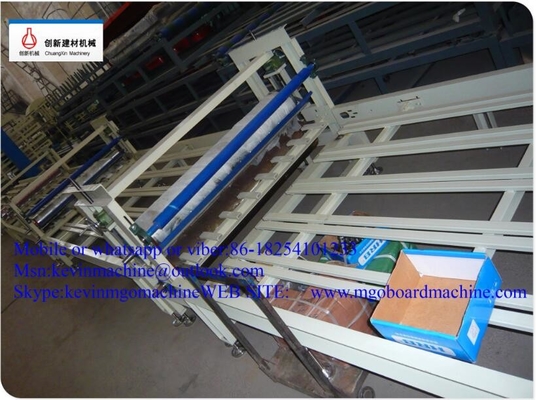

The equipment for mgo board is composed of board-making machine,glue-spreading and veneering-drying machine and glazing machine.according to the production and the automatic degree, this production line is divided into 6 models and three specifications ,such as large ,middle and small specification.The production line for mgo board has :production workshop ,finished product workshop and raw material warehouse .

2. Raw Material Delivery

Raw materials arrive at the plant via truck and rail transport in a variety of forms and packaging .mgo power is delivered via pneumatic trailer and piped into outside 150-ton mobile silos called a pig or guppy trailer .mgcl2 is delivered in liquid tanker truck and piped into outside 32,000-gallon vertical tank farm wood chips,the largest commodity is delivered in modular containers and stockpiled outside the plant.the comparably smaller balance of raw materials ,are deliver in bulk or standard bag format and stored inside the plant on pallets ,all the materials are sampled as they arrive and sent to the lab to maintain quality control.

TAKE 1200MM*2400MM*8MM MGO BOARD AN EXAMPLE IN CHINA

MGO BOARD CONSUMPTION COMPARABLE TABLE

| Names of materials | Each dosage |

| Magnesium | 2.978 yuan |

| Magnesium chloride | 1.23 yuan |

| Non-wovens | 0.85 yuan |

| Glass cloth | 1.05 yuan |

| Perlite | 0.62 yuan |

| Sawdust | 0.647 yuan |

3. The one machine can manufacture several board

1) simulated wooden board :After national grade testing ,its appearance is the same as that of the wooden board ,and its decorating effect, performance and performance-to-price atio are all better than the same board .with a large breadth ,it not only has the features which the wooden board owns ,such as nailed ,sawed ,planed and stuck,but also don’t need painting ,so it is green environment-friendly. For example : simulation beech board red(black) walaut board and bubinga(canthor).

2) Fireproof embossed door:after province-level detection ,it has such features:fireproof ,water-proof ,sound insulation ,heat preservation,variety and low cost.

3) Wall decorating mural painting:The board produced by the board-making machine can be made into various decorating art mural painting about landscape, flower-and-bird,insect-and-fish as well as character.the product gets popularity from customers with excellent quality and reasonable price

1 | Air-dry density | ≤ (Standard index)50kg/m2 | (Test Value) 30.0kg/ m2 |

| 2 | Drying shrinkage rate of the board | ≤0.08% | 0.015% |

| 3 | Anti-breaking load | ≥1400N | 5640N |

| 4 | Anti-impact | No breakage phenomenon such as cracking after three impacts | No breakage phenomenon such as cracking after three impacts |

| 5 | Thermal resistance of main section (T=90mm) | ≥1.35(m2.k)/w | ≥1.36(m2.k)/w |

| 6 | Thermal bridges area ratio | ≤8% | 2.22% |

| 7 | Sound reduction Index | | 36dB |

| 8 | Radioactivity | | None |

4) Vent-pipe :The polystylrene sandwich panle produced by this machine can be made into the vent-pipe used by the central air-conditioning system and all kinds of ventilation facility ,and the product is fireproof ,damp-proof,antiseptic,light-weight,heat-preservation ,long-performance life and low-price.In view of the above features,it wins much favor from users.

5) Building mould board :The strengthened mould plate with this technology can replace steel mould board ,bamboo&wood mould board and multiayer board .Being a high-profit product ,this board is applied widely in all kinds of concrete engineering with low-cost,high strength,long life and convenient to use .the board is high-profit product

In addition , in view of unique effect and great profit,various embossed board with decorative pattern and glazd pantile can replace carved wall board of wallpaper

4. Attention

The technology transfer fees of the composite mgo board:6000yuan (If you purchase our equipment,then the technology fee is free)

Sign the contract printed by Industry and Commerce B urear

We provide national grade certificate of key new product, quality and fireproofing grade ,and train2--3 technical personnel for you till then they master the recevant technology.

| Advantages |

| Number | Item | Content |

| 1 | Low cost | Low labour and raw materials costs |

| 2 | Long life | Up to 30 years |

| 3 | Recycling use | Reused for more than 8 times |

| 4 | Environment protection | Environment-friendly raw materials used |

| 5 | Flexible layout | adjusted according to your requirement |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!