Fiber Glass Materials Magnesium Oxide Forming Board Construction Equipments Machine

According to the production and the automatic degree, this production line is divided into 6 models and three specifications ,such as large ,middle and small specification.The production line for mgo board has :production workshop ,finished product workshop and raw material warehouse . workshop:100---1000m2,worker:3---6person,water:ordinary water,electricity:1.1—10KW(according to different scale)

EQUIPMENT CONTRIBUTION CONDITIONS

| frequency |

pressure |

equipment |

rooms |

capacity |

| 50HZ |

380V |

1.7million M2 |

12M*80M/9M*40M |

10KW-15KW |

Product features

The product manufactured by this equipment has following features:fireproof ,waterproof,environment protection and no toxicity .at the same time it is resistant against acid,alkali and aging. This product can be nailed,planed ,sawed and sticked.in the view of that its fireproofing grade is A .so our product will not be combustible when the fire is 800-1000C.at the same time when our product is fell to the water for a week ,there are not the following phenomenon such as chalking,deformation and warp.in light of there is not glue in the raw materials.so there is not formaldhyde and benzenz for our boards .

1 |

Air-dry density |

≤ (Standard index)50kg/m2 |

(Test Value) 30.0kg/ m2 |

| 2 |

Drying shrinkage rate of the board |

≤0.08% |

0.015% |

| 3 |

Anti-breaking load |

≥1400N |

5640N |

| 4 |

Anti-impact |

No breakage phenomenon such as cracking after three impacts |

No breakage phenomenon such as cracking after three impacts |

| 5 |

Thermal resistance of main section (T=90mm) |

≥1.35(m2.k)/w |

≥1.36(m2.k)/w |

| 6 |

Thermal bridges area ratio |

≤8% |

2.22% |

| 7 |

Sound reduction Index |

|

36dB |

| 8 |

Radioactivity |

|

None |

Structure principle and specification

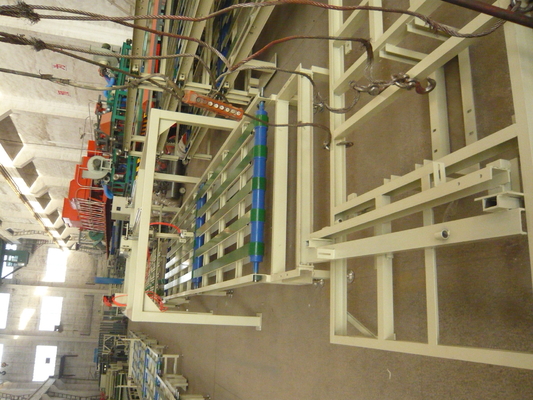

Production line for mgo board with fashionable design ,reasonable structure, stable running manufactures even thickness board in large production once through double ways roll-in technology .This production line is equipped with shaking device which can remove inside and outside air bubble .so our board is more compact .in addition,we use the no-woven cloth as the separating film to increase the toughness and the strength of the board .The machine can be adjusted arbitrarily ,and then produce the board with the thickness of 2-25mm,the biggest width of 1,300mm and unlimited length .so you can adjust the thickness of board at will.

The one machine can manufacture several board

simulated wooden board :After national grade testing ,its appearance is the same as that of the wooden board ,and its decorating effect, performance and performance-to-price atio are all better than the same board .with a large breadth ,it not only has the features which the wooden board owns ,such as nailed ,sawed ,planed and stuck,but also don’t need painting ,so it is green environment-friendly. For example : simulation beech board red(black) walaut board and bubinga(canthor).

Fireproof embossed door:after province-level detection ,it has such features:fireproof ,water-proof ,sound insulation ,heat preservation,variety and low cost.

Wall decorating mural painting:The board produced by the board-making machine can be made into various decorating art mural painting about landscape, flower-and-bird,insect-and-fish as well as character.the product gets popularity from customers with excellent quality and reasonable price

Vent-pipe :The polystylrene sandwich panle produced by this machine can be made into the vent-pipe used by the central air-conditioning system and all kinds of ventilation facility ,and the product is fireproof ,damp-proof,antiseptic,light-weight,heat-preservation ,long-performance life and low-price.In view of the above features,it wins much favor from users.

Building mould board :The strengthened mould plate with this technology can replace steel mould board ,bamboo&wood mould board and multiayer board .Being a high-profit product ,this board is applied widely in all kinds of concrete engineering with low-cost,high strength,long life and convenient to use .the board is high-profit product

In addition , in view of unique effect and great profit,various embossed board with decorative pattern and glazd pantile can replace carved wall board of wallpaper

| Serial number |

Inspection items |

Standard requirement

(thickness 8mm)

|

inspection results |

| 1 |

Flexural strength |

>8.0 |

10.3 |

| 2 |

Impact strength |

>1.5 |

4.84 |

| 3 |

performance density |

0.7<p<1.0 |

0.92 |

| 4 |

Back to halogen resistance |

No water, no get damp |

No water, no get damp |

| 5 |

Dry shrinkage |

<0.3 |

0.21 |

| 6 |

Wet bilge rate |

<0.6 |

0.40 |

| 7 |

With screw force |

>15 |

61 |

| 8 |

The chloride ion content |

<10 |

2.96 |

| 9 |

The factory of moisture content |

<8 |

7.5 |

|

10

|

incombustible

|

The average temperature in the furnace |

<50

|

8

|

| The average combustion duration |

<20

|

0

|

| The average mass loss rate |

<50

|

47.5

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!