Fireproof Board1300mm Width Wall Decorative Panel Magnesium Oxide Board Machine

Mgo board is a kind of new green and fireproof building material which is used in place of traditional gypsum drywall as partition wall and ceiling covering material and sheathing. MgO boards could be used anywhere Gypsum boards or dry walls could be used, such as wall board, backer board, underlayment, siding etc. MgO boards do have many advantages over gypsum boards or dry walls which make them the material of choice for new constructions and renovations.

Raw Material

Magnesium oxide(MGO), magnesium chloride, perlite, Wood dust, fiberglass mesh, non-woven cloth etc.

product features

| Product Name |

magnesium oxide board |

| Standard Size |

1220mmx2440mm or 1200mmx2400mm |

| Maximum Width |

1220mm |

| Maximum Length |

3050mm |

| Thickness |

3mm-25mm |

| Density |

0.8-1.2g/cm³

(Normal standard is 0.9-1.0g/cm³)

|

| Basic Color |

White or Grey |

| Surface |

Thin slurry surface |

| Moisture Content |

≤10% |

| Water Absorbing |

≤40% |

| Bending Strength |

12-25Mpa |

| Fire Resistance |

Incombustibility Class A1 |

| Thermal Conductivity |

0.19W/(m·K) |

| The rate of deformation |

when pick up the moisture:0.26% |

| The shrinking rate |

when heated:1.0% |

| Security |

100% does not include asbestos,formaldehyde,benzene |

| Radioactivity |

Not limited by the scope of application |

machine features

| Equipment parameters |

Description |

| Raw material |

Mgo/mgcl2/fiber glass mesh |

| Texture of material |

steel |

| Automatic degree |

Fully/semi automatic |

| Finsihed board size |

Thickness:2-25mm,unlimited length ,width:1300mm |

| Color |

Blue ,red,etc |

| Capacity |

Maximum 1500 sheets/shift(8 hours) |

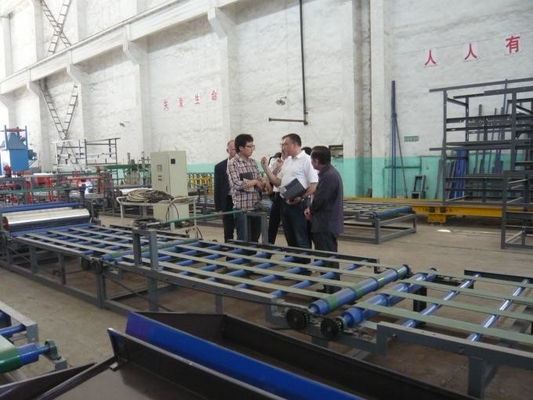

Production line for mgo board with fashionable design ,reasonable structure, stable running manufactures even thickness board in large production once through double ways roll-in technology .This production line is equipped with shaking device which can remove inside and outside air bubble .so our board is more compact .in addition,we use the no-woven cloth as the separating film to increase the toughness and the strength of the board .The machine can be adjusted arbitrarily ,and then produce the board with the thickness of 2-25mm,the biggest width of 1,300mm and unlimited length .so you can adjust the thickness of board at will.

The one machine can manufacture several board

Fireproof embossed door:

after province-level detection ,it has such features:fireproof ,water-proof ,sound insulation ,heat preservation,variety and low cost.

Wall decorating mural painting:

The board produced by the board-making machine can be made into various decorating art mural painting about landscape, flower-and-bird,insect-and-fish as well as character.the product gets popularity from customers with excellent quality and reasonable price

Vent-pipe :

The polystylrene sandwich panle produced by this machine can be made into the vent-pipe used by the central air-conditioning system and all kinds of ventilation facility ,and the product is fireproof ,damp-proof,antiseptic,light-weight,heat-preservation ,long-performance life and low-price.In view of the above features,it wins much favor from users.

Building mould board :

The strengthened mould plate with this technology can replace steel mould board ,bamboo&wood mould board and multiayer board .Being a high-profit product ,this board is applied widely in all kinds of concrete engineering with low-cost,high strength,long life and convenient to use .the board is high-profit product

Our Services

We not only supply MgO Board Production Lines, but also provide other services like:

1. Assemble machines at customer's factory

2. Production techniques training

3. Machine up-grade and maintenance

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!