Product Description:

The Wall Panel Forming Machine is an advanced and highly efficient piece of equipment designed to meet the growing demands of the construction and furniture manufacturing industries. With a robust production capacity of 1500 sheets per day, this machine ensures high productivity and consistent quality, making it an ideal choice for businesses seeking to enhance their manufacturing processes. Whether you are involved in producing wall panels for construction or components for furniture, this machine offers exceptional performance and reliability.

One of the standout features of this Wall Panel Forming Machine is its integration with a Delta touch screen interface. The Delta touch screen provides an intuitive and user-friendly control system, allowing operators to easily monitor and adjust the machine’s settings for optimal performance. This advanced control panel enhances operational efficiency, reduces downtime, and ensures precise control over the forming process, which is crucial for maintaining the high standards required in wall panel production.

Operating at a voltage of 380V, 50HZ, and utilizing a 3-phase power supply, the machine is designed for industrial use and ensures stable and efficient energy consumption. The 380V voltage specification allows the machine to handle heavy-duty operations without compromising performance, making it suitable for large-scale manufacturing environments. This electrical configuration contributes to the machine’s durability and consistent output quality.

Durability is a key consideration in any industrial equipment, and the Wall Panel Forming Machine excels in this regard with a useful life span of up to 20 years. This long service life ensures that your investment in this machinery will provide sustained value over two decades, minimizing the need for frequent replacements or costly repairs. The machine’s robust construction and high-quality components contribute to its longevity, making it a reliable cornerstone of your production line.

While primarily designed for wall panel formation, this machine shares technological similarities with other automatic production equipment such as the Double Wall Paper Cup Machine and Automatic Furniture Making Machine. Like the Double Wall Paper Cup Machine, which automates the production of paper cups with precision and speed, the Wall Panel Forming Machine automates the shaping and forming process of wall panels, significantly increasing throughput and reducing manual labor. Additionally, its automation features align with those found in Automatic Furniture Making Machines, which streamline furniture component production to achieve consistent quality and scale.

The Wall Panel Forming Machine stands out as a versatile and indispensable tool in modern manufacturing settings. Its combination of high production capacity, advanced Delta touch screen controls, industrial-grade voltage requirements, and impressive durability make it an excellent investment for companies aiming to optimize their production lines. Whether you are upgrading your existing machinery or establishing a new manufacturing facility, this wall panel forming equipment offers a reliable and efficient solution to meet your needs.

In summary, this Wall Panel Forming Machine is a powerful and reliable choice for industries involved in wall panel manufacturing and related sectors. Its ability to produce up to 1500 sheets daily, coupled with the advanced Delta touch screen for streamlined operation, ensures maximum productivity and ease of use. The machine’s voltage specifications of 380V, 50HZ, and 3-phase power supply provide the stability required for continuous industrial use, while its impressive 20-year useful life guarantees long-term operational reliability. By incorporating technology and features comparable to those found in Double Wall Paper Cup Machines and Automatic Furniture Making Machines, this machine exemplifies the future of automated manufacturing equipment.

Applications:

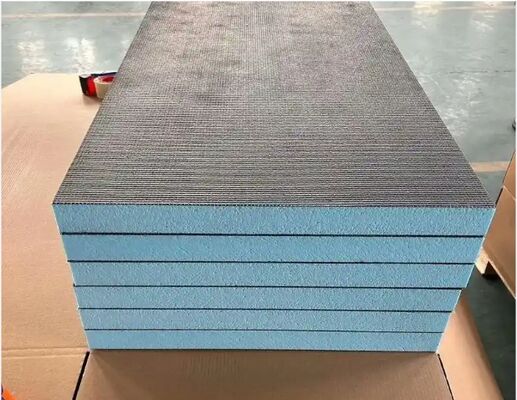

The Wall Panel Forming Machine, model CX-1, manufactured by Shandong Chuangxin, is a state-of-the-art Automatic Furniture Making Machine designed for efficient and precise wall panel production. Originating from China and certified with CE, this machine ensures high-quality performance and safety standards. Its robust design allows it to handle material thicknesses ranging from 0.3 to 0.8mm, making it versatile for various wall panel requirements. The machine operates on a 380V voltage system and can produce panels with lengths customizable between 2270mm and 3000mm, tailored to customer specifications.

This Wall Panel Machine is ideal for use in a variety of application occasions and scenarios. It is extensively utilized in the furniture manufacturing industry, where automation and precision are critical for producing high-quality wall panels efficiently. Its ability to customize panel length and color according to customer requirements makes it suitable for bespoke furniture projects and interior decoration firms. Additionally, construction companies benefit from this machine by producing durable and aesthetically pleasing wall panels used in residential and commercial buildings.

In manufacturing environments where speed and consistency are paramount, the CX-1 Wall Panel Forming Machine excels by automating the production process, reducing labor costs, and increasing output. It is especially beneficial in factories that produce furniture or wall panels in large quantities, ensuring uniformity and reducing material waste. The packaging of the machine in a sturdy wood package ensures safe delivery within approximately 40 days, with flexible payment terms such as LC and T/T facilitating smooth transactions.

Though primarily designed as a Wall Panel Machine, the technology and automation principles behind the CX-1 are comparable to those found in other machinery, such as the Double Wall Paper Cup Machine, which also emphasizes automation and precision in product forming. These machines share a common goal of improving production efficiency and product quality through advanced engineering.

With a minimum order quantity of just one unit and a competitive price of $30,000, the Shandong Chuangxin CX-1 Wall Panel Forming Machine is an excellent investment for businesses looking to enhance their manufacturing capabilities. Its adaptability, reliability, and advanced features make it a preferred choice for industries focused on automatic furniture making and wall panel production.

Customization:

Shandong chuangxin proudly presents the CX-1 Wall Panel Forming Machine, a high-quality product made in China with CE certification. This Automatic Furniture Making Machine is designed for efficiency and durability, featuring a raw material feed system that is fully automatic to streamline your production process.

The CX-1 model supports panel lengths ranging from 2270mm to 3000mm, which can be customized to meet your specific project requirements. With a minimum order quantity of just 1 unit and a competitive price of 30,000 USD, this machine offers excellent value for manufacturers looking to enhance their capabilities.

Our Wall Panel Forming Machine boasts features such as fast construction and anti-earthquake capabilities, ensuring reliable performance and safety during operation. The machine comes with a 12-month guaranty and is packaged securely in a wood package to ensure safe delivery within 40 days.

Payment terms are flexible, accepting LC and T/T methods to accommodate your business needs. With a useful life of 20 years, this machine is a long-term investment for your production line.

Whether you are producing wall panels or seeking equipment similar to a Double Wall Paper Cup Machine, the CX-1 Automatic Furniture Making Machine offers versatility and precision. Trust Shandong chuangxin for innovative solutions in your manufacturing process.

Support and Services:

Our Wall Panel Forming Machine is designed to deliver high efficiency and precision in manufacturing wall panels. For technical support, our team of experts is available to assist with installation, operation, maintenance, and troubleshooting to ensure optimal machine performance.

We provide comprehensive services including on-site training for operators, routine maintenance schedules, and prompt repair services to minimize downtime. Spare parts and upgrades are also available to keep your machine running smoothly and up-to-date with the latest technology.

To maximize the lifespan and productivity of your Wall Panel Forming Machine, we recommend following the provided operation manuals and maintenance guidelines. Our support team can offer customized solutions tailored to your specific production needs.

Whether you require assistance with machine setup, software updates, or technical consultations, our dedicated support staff is committed to providing timely and effective service to help you achieve the best results from your investment.

Packing and Shipping:

The Wall Panel Forming Machine is carefully packaged to ensure it arrives in perfect condition. Each unit is securely wrapped with protective materials and placed in a sturdy wooden crate to prevent any damage during transportation. The packaging is designed to withstand rough handling and environmental factors, ensuring the machine reaches you safely.

For shipping, we offer multiple options including sea freight, air freight, and land transportation to accommodate your location and delivery timeline. Our logistics team coordinates all aspects of the shipment, from loading to customs clearance, providing you with timely updates throughout the process. We ensure that the Wall Panel Forming Machine is delivered efficiently and on schedule, ready for installation and operation.

FAQ:

Q1: What is the brand and model of the Wall Panel Forming Machine?

A1: The Wall Panel Forming Machine is from the brand Shandong Chuangxin, and the model number is CX-1.

Q2: Where is the Wall Panel Forming Machine manufactured?

A2: The machine is manufactured in China.

Q3: What certifications does the Wall Panel Forming Machine have?

A3: The machine is CE certified, ensuring it meets European safety and quality standards.

Q4: What is the minimum order quantity and price for the Wall Panel Forming Machine?

A4: The minimum order quantity is 1 unit, and the price is $30,000 per machine.

Q5: What are the packaging details and delivery time for the Wall Panel Forming Machine?

A5: The machine is packaged in a wood package for safe transportation, and the delivery time is approximately 40 days.

Q6: What are the accepted payment terms for purchasing the Wall Panel Forming Machine?

A6: We accept LC (Letter of Credit) and T/T (Telegraphic Transfer) as payment terms.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!