Product Description:

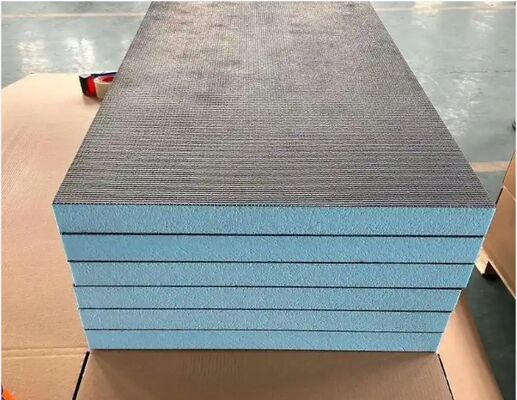

The Wall Panel Forming Machine is a highly advanced piece of equipment designed to meet the rigorous demands of modern manufacturing environments. Engineered with precision and built for durability, this machine excels in producing high-quality wall panels that offer exceptional fire resistance, making it an ideal choice for construction and interior design applications. One of the standout features of this machine is its outstanding fireproof capability; the panels produced can withstand fire for up to 4 hours under a temperature of 1000 degrees Celsius. This level of fire resistance ensures enhanced safety and compliance with stringent building codes, providing peace of mind to builders and end-users alike.

Constructed to handle material thicknesses ranging from 0.3mm to 0.8mm, the Wall Panel Forming Machine offers remarkable versatility. This flexibility allows manufacturers to produce panels tailored to different specifications and applications, whether for residential, commercial, or industrial use. The ability to work with a wide range of material thicknesses also means that the machine can adapt easily to changing production requirements, making it a valuable asset for growing businesses.

Incorporating cutting-edge technology, the machine is equipped with a Delta touch screen control system. This user-friendly interface simplifies operation, allowing operators to easily monitor and adjust the production process in real time. The intuitive touch screen enhances efficiency, reduces the likelihood of errors, and streamlines workflow, which is essential for maintaining high productivity levels. The integration of such advanced controls underscores the machine’s commitment to combining innovation with practical usability.

Powered by a standard 380V voltage supply, the Wall Panel Forming Machine is designed for compatibility with industrial power systems, ensuring stable and reliable operation. This robust power configuration supports continuous operation and high output rates, which are critical for meeting tight production schedules and large-scale manufacturing demands. Additionally, the machine's electrical components are selected to optimize energy consumption without compromising performance, making it both cost-effective and environmentally conscious.

Recognizing the importance of long-term reliability, the Wall Panel Forming Machine comes with a 12-month guarantee. This warranty reflects the manufacturer’s confidence in the machine’s quality and durability, offering customers assurance and support post-purchase. The guarantee covers essential components and workmanship, ensuring that any issues encountered within the first year of operation are promptly addressed, minimizing downtime and maintaining production continuity.

Beyond its core functions, the Wall Panel Forming Machine shares technological synergies with other advanced machinery such as the Double Wall Paper Cup Machine and Automatic Furniture Making Machine. These machines represent the forefront of automation in their respective fields, emphasizing precision, efficiency, and quality. The Wall Panel Forming Machine complements these devices by contributing to a comprehensive manufacturing ecosystem where automation and innovation drive superior product outcomes. Whether integrated into a larger production line or operated independently, this machine stands as a testament to the evolution of automated manufacturing solutions.

In conclusion, the Wall Panel Forming Machine is an indispensable tool for manufacturers seeking to produce fireproof wall panels with precision and efficiency. Its capability to handle material thicknesses from 0.3 to 0.8mm, combined with the advanced Delta touch screen controls and a reliable 380V power system, makes it a versatile and dependable choice. The 12-month guarantee further enhances its appeal by providing customers with confidence in their investment. As part of a broader family of innovative machinery, including the Double Wall Paper Cup Machine and Automatic Furniture Making Machine, this machine exemplifies the future of automated production in the furniture and construction industries.

Applications:

The Shandong chuangxin Wall Panel Forming Machine, model CX-1, is a state-of-the-art automatic furniture making machine designed to meet the high demands of modern manufacturing industries. Originating from China and certified with CE, this machine guarantees quality and reliability, making it an excellent investment for businesses looking to enhance production efficiency. With a minimum order quantity of just 1 unit and a competitive price of 30,000 USD, it offers great value for manufacturers seeking advanced technology in wall panel production.

This machine is ideal for various application occasions and scenarios, especially in the construction and furniture industries. It is perfectly suited for factories producing wall panels used in residential, commercial, and industrial buildings. Thanks to its automatic raw material feed system and 380V voltage compatibility, the CX-1 ensures smooth and continuous operation, minimizing downtime and maximizing productivity. The inclusion of a user-friendly Delta touch screen allows operators to control and monitor the machine’s performance with ease, ensuring consistent product quality.

In addition to wall panel forming, the Shandong chuangxin CX-1 is versatile enough to be used alongside other equipment such as the Double Wall Paper Cup Machine, enhancing overall manufacturing workflows. This integration is especially beneficial for companies involved in multi-product manufacturing lines, providing seamless operation and increased output. The CX-1’s robust construction, backed by a 12-month guarantee and an impressive 20-year useful life, ensures long-term durability and sustained performance in demanding production environments.

The packaging details include a sturdy wood package to protect the machine during transit, with a delivery time of approximately 40 days. Payment terms are flexible, accepting LC and T/T, catering to international buyers. Whether you are upgrading your existing production line or establishing a new facility, the Shandong chuangxin Wall Panel Forming Machine CX-1 is an essential asset for efficient and automated manufacturing. Its compatibility with accessories like the Double Wall Paper Cup Machine further broadens its application possibilities, making it a valuable addition to any advanced furniture or construction material production setup.

Customization:

Shandong Chuangxin proudly presents the CX-1 Wall Panel Forming Machine, an advanced Automatic Furniture Making Machine designed to meet your production needs with efficiency and precision. Originating from China and certified with CE, this model ensures high quality and compliance with international standards.

The CX-1 features an automatic raw material feed system, enhancing productivity and reducing manual labor. With a production capacity of 1500 sheets, it is ideal for large-scale manufacturing. The machine operates at 380V and comes with a customizable color option to suit your brand requirements.

We offer this Double Wall Paper Cup Machine at a competitive price of $30,000, with a minimum order quantity of just one unit. The machine is securely packed in a wooden package to ensure safe delivery within 40 days.

Payment terms are flexible, accepting LC and T/T methods. Additionally, the CX-1 Wall Panel Forming Machine comes with a 12-month guarantee, providing you peace of mind and reliable after-sales support.

Choose Shandong Chuangxin’s Automatic Furniture Making Machine for your next project and experience top-tier performance and customization tailored to your needs.

Support and Services:

Our Wall Panel Forming Machine is designed to deliver high precision and efficiency in producing durable wall panels for various construction needs. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services.

Technical Support:

Our skilled technical team is available to assist you with installation guidance, operation instructions, and troubleshooting. We provide detailed manuals and video tutorials to help you understand the machine's features and maintenance requirements. Should you encounter any operational issues, our experts are ready to diagnose and resolve problems promptly to minimize downtime.

Maintenance Services:

Regular maintenance is crucial to keep your Wall Panel Forming Machine running smoothly. We offer scheduled maintenance services including inspection, lubrication, parts replacement, and system calibration. Our goal is to prevent unexpected failures and extend the service life of your equipment.

Spare Parts Availability:

We maintain an inventory of genuine spare parts to ensure quick replacement and reduce machine downtime. All parts are manufactured to meet the original specifications, guaranteeing compatibility and reliability.

Training Programs:

To maximize the benefits of your Wall Panel Forming Machine, we provide training sessions for your operators and maintenance staff. These programs cover machine operation, safety protocols, and routine maintenance procedures.

Upgrades and Customization:

Our engineering team can assist with machine upgrades and customization to meet specific production requirements or to incorporate the latest technological advancements.

Customer Satisfaction:

We are committed to delivering excellent after-sales service and support. Your satisfaction and success in using our Wall Panel Forming Machine are our top priorities.

Packing and Shipping:

Our Wall Panel Forming Machine is carefully packaged to ensure it arrives at your site in perfect condition. The machine is securely wrapped with protective materials to prevent any damage during transit. It is then placed in a sturdy wooden crate that is custom-built to fit the machine's dimensions, providing additional protection against shocks and vibrations.

For shipping, we offer multiple options including sea freight, air freight, and land transportation, depending on your location and urgency. The packaging is designed to withstand long-distance transportation and handling. All necessary loading and unloading instructions are included to facilitate safe and efficient delivery.

Before shipment, the machine undergoes thorough inspection and testing to guarantee quality and functionality. We also provide detailed documentation, including operation manuals, installation guides, and warranty information, all securely packed with the machine.

Our logistics team coordinates with reliable carriers to ensure timely delivery. Tracking information will be shared with you once the shipment is dispatched, allowing you to monitor the progress until it reaches your destination.

In summary, the Wall Panel Forming Machine is packaged with utmost care and shipped using trusted methods to ensure it arrives safely and ready for installation.

FAQ:

Q1: What is the brand and model number of the Wall Panel Forming Machine?

A1: The Wall Panel Forming Machine is manufactured by Shandong Chuangxin, and the model number is CX-1.

Q2: Where is the Wall Panel Forming Machine produced?

A2: This machine is made in China.

Q3: What certification does the Wall Panel Forming Machine have?

A3: The machine is CE certified, ensuring it meets European safety and quality standards.

Q4: What is the minimum order quantity and price for the Wall Panel Forming Machine?

A4: The minimum order quantity is 1 unit, and the price is $30,000 per unit.

Q5: What are the packaging and delivery details for the Wall Panel Forming Machine?

A5: The machine is packaged in a wood package for secure transportation, with a delivery time of approximately 40 days.

Q6: What payment terms are accepted for purchasing the Wall Panel Forming Machine?

A6: Payment terms accepted include Letter of Credit (LC) and Telegraphic Transfer (T/T).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!